In the cosmetics industry, lipstick is one of the most common cosmetic products, and the aesthetics of its packaging directly influences consumer purchasing decisions. Lipstick labeling machines, as key automated equipment in cosmetics production lines, are crucial for ensuring labeling accuracy, impacting not only product appearance but also production efficiency and company costs. However, in actual production, lipstick labeling machines can still experience labeling inaccuracies, which not only exposes companies to the risk of rework and waste but also damages their brand image. So, what causes labeling inaccuracies in lipstick labeling machines? How can companies effectively address this issue? This article will delve into these issues.

1. Common Causes of Inaccurate Lipstick Labeling

Before analyzing solutions, we need to first understand the main causes of inaccurate lipstick labeling. Generally, the issues focus on the following:

Unstable product positioning: Lipsticks can vary slightly in size, shape, and weight. If product positioning on the production line is unstable, the labeling machine can easily misalign its labeling position. For example, varying heights or tilted lipstick tubes can lead to misaligned labeling.

Unstable label feeding: If the label feeding system of a lipstick labeler experiences issues like uneven label feeding speed, curled labels, or static electricity, these issues can lead to inaccurate label placement. Uneven label tension or curled edges are particularly prone to causing deviations.

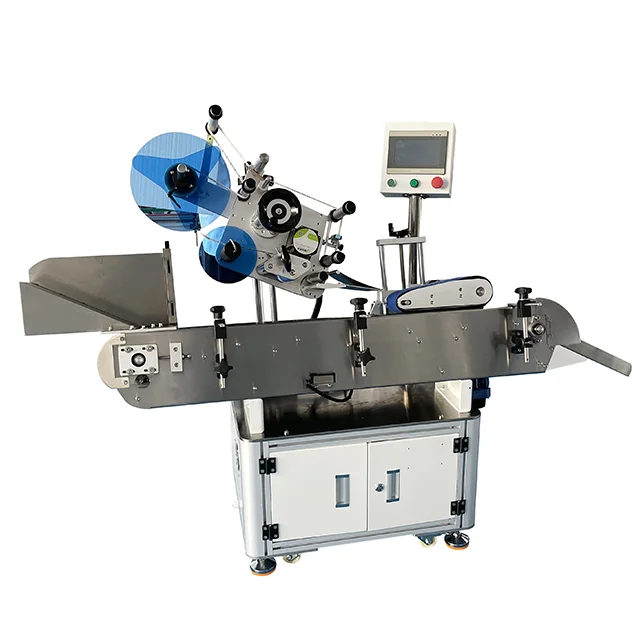

Improper labeling mechanism adjustment: The labeling mechanism of a labeler includes rollers, a pressure roller, and a glue dispenser. If these components are improperly adjusted or become worn or loose after prolonged use, accurate pressure and placement during label application will be difficult to achieve.

Sensor failure or insufficient sensitivity: Lipstick labelers typically rely on photoelectric or mechanical sensors to detect product position for automatic alignment. Sensor failure, dust accumulation, or insufficient sensitivity can lead to misjudgment and cause labeling errors.

Environmental factors: Temperature, humidity, and dust in the production environment can also affect labeling accuracy. For example, high humidity can cause label glue to absorb moisture prematurely, resulting in misalignment during label application; dust accumulation can also affect sensor recognition.

2. Solutions

To address these issues, companies can effectively improve the labeling accuracy of lipstick labelers by focusing on equipment adjustment, process optimization, and environmental management.

2.1 Optimizing the Product Conveying and Positioning System

Ensuring the stability of lipstick products during conveying is essential for accurate labeling. The following measures can be taken:

Adjusting the conveyor belt speed and buffering devices ensures smooth product conveying and prevents shaking or tilting.

Using positioning fixtures or guides: Designing adjustable guides or fixtures for different lipstick sizes ensures that each lipstick remains vertical and stable during labeling.

Regularly inspecting product specifications ensures that the height, diameter, and weight of lipsticks on the production line are within acceptable tolerances to prevent abnormal products from affecting labeling.

2.2 Improving the Stability of the Label Feed System

The stability of the label feed system directly impacts labeling accuracy. Possible measures include:

Optimizing the label feed speed ensures that the label feed speed matches the lipstick movement speed to avoid "catching up" or "lagging."

Using anti-static devices reduces label deviation caused by static cling.

Regularly inspecting the label roll ensures that the roll is flat to avoid uneven tension or curling. Selecting the appropriate label material: For soft or easily deformable labels, choose materials that are stretch-resistant and resistant to humidity fluctuations to ensure accurate labeling.

2.3 Fine-tuning the labeling mechanism

The accuracy of the labeling mechanism is crucial and requires fine-tuning based on different production batches:

Adjusting roller pressure: Excessive pressure may cause the label to shift, while too little pressure may result in a loose label. Adjust the pressure based on the lipstick material.

Replacing worn parts: The pressure roller, roller, and glue dispenser, which are used over time, should be regularly replaced or maintained to ensure consistent labeling.

Adjusting the labeling angle: Lipstick is a cylindrical product, and improper labeling angles can easily cause misalignment. This can be addressed by fine-tuning the angle or using a rotary labeling mechanism.

2.4 Inspecting and Maintaining Sensors

As a key component of automatic alignment, sensors require regular inspection and calibration:

Cleaning the sensor: Prevent dust or glue residue from affecting recognition.

Adjusting sensitivity: Adjust the sensor sensitivity based on the material and color of the product to ensure accurate recognition.

Adding auxiliary positioning sensors: For high-speed production lines, multiple detection points can be added to reduce false positives. 2.5 Improving the Production Environment

Labeling accuracy is closely related to the production environment. Improving environmental conditions can also reduce the problem of inaccurate labeling:

Controlling temperature and humidity: Maintaining stable temperature and humidity in the production workshop prevents labels from absorbing moisture or prematurely drying the glue.

Reducing dust: Regularly clean the production line and air filtration system to ensure the sensor and label surfaces are clean.

Avoiding interference from strong light: Some photoelectric sensors are sensitive to strong light. Adjusting the light source or light shield can improve recognition.

3. Introducing Intelligent and Automated Technologies

With the intelligent upgrade of cosmetics production, traditional labeling machines are gradually transitioning to intelligent equipment. Companies can consider implementing the following technologies to improve labeling accuracy:

Visual recognition system: Using a camera to scan product and label position, real-time adjustments are made for more accurate labeling, automatically compensating for even slight variations in product size.

Automatic deviation correction system: Using a rotating guide wheel or servo control system, the system automatically adjusts the angle during labeling to ensure the label fits the cylindrical lipstick surface without deviation. Intelligent Monitoring and Data Analysis: By monitoring production line data, the source of labeling errors is analyzed in real time, and automatic alarms or adjustments are issued, reducing manual intervention and improving efficiency and accuracy.

4. Enterprise Case Studies

A well-known cosmetics company experienced labeling deviation issues with traditional lipstick labeling machines, resulting in a rework rate as high as 5%. Through the following measures, the company successfully reduced labeling inaccuracy to less than 1%:

Redesigned the lipstick conveyor guide to ensure each lipstick remains vertical and stable before labeling.

Added an anti-static device to address label adsorption deviation.

Replaced worn pressure wheels and rollers, and regularly adjusted roller pressure.

Introduced a visual recognition system to adjust labeling angle and position in real time.

Improved the workshop environment to control humidity and reduce dust accumulation.

The results showed that through system optimization and intelligent upgrades, labeling accuracy was significantly improved, production efficiency increased by approximately 20%, and manual rework costs were reduced. The problem of inaccurate labeling in lipstick labeling machines is a common challenge faced by cosmetics manufacturers. However, this issue can be effectively addressed by optimizing the system in areas such as product transport, label supply, labeling mechanism adjustment, sensor maintenance, and production environment management, supplemented by intelligent technology upgrades. High-precision labeling not only ensures a uniform and aesthetically pleasing lipstick appearance, but also improves production efficiency and reduces costs, playing a significant role in enhancing brand image and market competitiveness.

With the cosmetics industry's growing demand for automation and intelligence, lipstick labeling machines will increasingly prioritize precision and stability, and intelligent labeling systems will become an industry trend. When selecting and using lipstick labeling machines, companies should focus on equipment quality, technological advancements, and after-sales service to ensure that their labeling lines consistently operate efficiently and accurately.

As a professional lipstick labeling machine supplier, Beilt is committed to providing cosmetics companies with high-precision, intelligent labeling solutions. With advanced equipment technology, stable production performance and comprehensive after-sales service, Beilt not only helps companies solve problems such as inaccurate labeling and low production efficiency, but also helps brands improve the aesthetics of packaging and market competitiveness, and achieve efficient operation of automated production lines.

www.beiltpack.com

beiltpack