In industries where flammable gases, combustible dust, or volatile chemicals are present, electrical safety is not an option but a core operational requirement. From offshore oil platforms to chemical processing plants and military facilities, electrical distribution systems must withstand harsh environments while preventing ignition risks. The explosion proof junction box plays a critical role in these scenarios by ensuring safe cable distribution, secure electrical connections, and long-term operational stability under extreme conditions. In this blog post, MINMILE, as high performance explosion-proof equipment manufacturer, will share information on explosion proof electrical junction box design for high-risk industrial sites.

Explosion Proof Electrical Junction Box as Safety-Critical Component

An explosion proof electrical junction box is designed to contain internal sparks, arcs, or heat generated by electrical connections so they cannot ignite surrounding hazardous atmospheres. Unlike standard enclosures, these boxes are engineered to withstand internal explosions and prevent flame propagation to the external environment.

In chemical plants, oil refining facilities, and oil exploitation sites, electrical systems are often exposed to flammable vapors. A properly designed explosion-proof junction box acts as a containment barrier, protecting both personnel and infrastructure. Its role becomes even more critical in offshore oil platforms and oil tankers, where confined spaces and continuous exposure to corrosive environments significantly increase risk.

Application Scenarios in Hazardous Industrial Environments

The versatility of explosion proof electrical junction box solutions allows them to be deployed across a wide range of high-risk industries.

In chemical processing plants, these enclosures are commonly used for cable distribution when installing electrical appliances and industrial lamps. They also provide reliable connection points for control circuits operating near reactors, storage tanks, and pipelines.

Oil refining and oil exploitation sites rely on explosion-proof junction boxes for stable power distribution in zones where hydrocarbons are continuously present. On offshore oil platforms, they must withstand salt spray, high humidity, and mechanical vibration while maintaining explosion containment integrity.

In oil tankers, junction boxes are installed in pump rooms, deck areas, and cargo handling zones, where safety regulations are particularly strict. Military facilities and defense-related hazardous areas also require such enclosures to support mission-critical electrical systems under extreme conditions.

Supporting Heat Tracing Systems and High-Power Electric Heaters

One of the most demanding applications for an explosion proof electrical junction box is its use in heat tracing systems and high-power electric heaters. Heat tracing is essential in pipelines and vessels to prevent freezing, maintain fluid viscosity, or ensure stable chemical reactions.

These systems often operate at high power levels, generating significant heat and requiring secure cable terminations. Explosion-proof junction boxes designed for such applications provide sufficient internal space for wiring, robust terminals for high current loads, and materials that can tolerate elevated temperatures without compromising safety.

By safely distributing power to heat tracing circuits on site, these junction boxes help maintain continuous operations in cold climates or process-critical installations, particularly in oil and gas and chemical industries.

Structural Design and Material Engineering

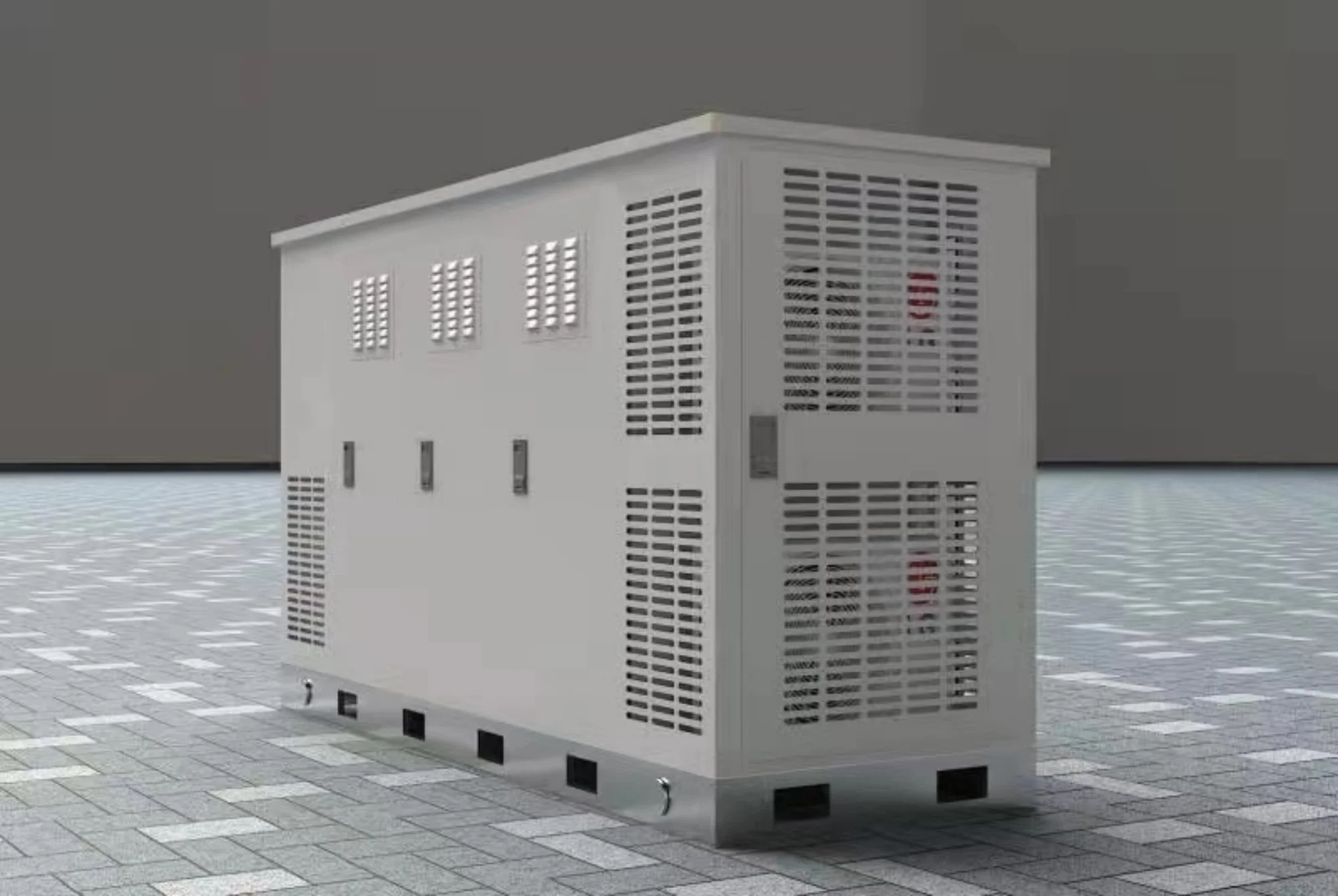

Modern explosion proof electrical junction box designs emphasize both mechanical strength and corrosion resistance. A common and highly effective construction uses an aluminum alloy enclosure combined with stainless steel exposed fasteners.

The aluminum alloy body offers several advantages. It provides excellent strength-to-weight ratio, making installation easier while still withstanding internal explosion pressures. Aluminum alloys also deliver good thermal conductivity, helping dissipate heat generated by internal electrical components.

Stainless steel fasteners enhance durability and resistance to corrosion, especially in offshore oil platforms and marine environments. This combination ensures long service life even when exposed to salt spray, chemical fumes, or high humidity.

Aesthetic Design Meets Industrial Functionality

While safety and performance are paramount, the visual design of industrial equipment is increasingly valued. A well-designed explosion proof electrical junction box with a clean, professional appearance contributes to orderly installations and easier maintenance.

Smooth enclosure surfaces, precise machining, and uniform finishes reflect manufacturing quality and facilitate cleaning in environments where dust or chemical residues accumulate. The use of aluminum alloy enclosures also allows for refined surface treatments that improve both corrosion resistance and visual appeal.

This balance between aesthetics and functionality is particularly appreciated in modern industrial plants where standardized layouts and visual inspections are part of routine safety management.

Flexible Mounting Options for Diverse Installations

Different industrial sites require different installation approaches, and explosion proof electrical junction box systems are designed with flexibility in mind. Multiple mounting types are available to adapt to site-specific conditions and customer requirements.

Hanging mounting configurations are commonly used when junction boxes must be suspended from structures, ceilings, or pipe racks. This approach is practical in offshore platforms and processing plants where floor space is limited.

Stand floor mounting options are suitable for heavy-duty installations or areas where easy access is required for maintenance. These mounting types ensure stability and simplify cable routing in complex industrial layouts.

The ability to select appropriate mounting solutions improves installation efficiency and reduces long-term operational challenges.

Cable Entry Design for Reliable Electrical Connections

Cable entry design is a critical aspect of explosion-proof junction box performance. To meet diverse application needs, modern enclosures support various cable entry configurations compatible with both rubber cables and armored cables.

Rubber cable entries are typically used in flexible installations or areas with frequent movement, while armored cable entries provide enhanced mechanical protection in harsh environments. Proper sealing of cable entries is essential to maintain explosion-proof integrity and environmental protection ratings.

By offering customizable cable entry options, explosion proof electrical junction box manufacturers enable engineers to optimize safety, durability, and ease of installation across different projects.

Compliance with Hazardous Area Standards

An explosion proof electrical junction box must comply with international hazardous area standards to be deployed legally and safely. While specific certifications vary by region, the underlying design principles remain consistent: containment of internal explosions, prevention of flame transmission, and resistance to environmental stress.

Compliance ensures that junction boxes can be confidently used in classified zones within chemical plants, oil refineries, and offshore installations. It also simplifies project approval processes and supports global deployment of standardized equipment.

Installation and Maintenance Considerations

Correct installation is essential to realize the full safety benefits of an explosion proof electrical junction box. Proper torque on fasteners, correct cable gland selection, and adherence to manufacturer guidelines all contribute to maintaining explosion containment performance.

Maintenance procedures should include periodic inspections of enclosure integrity, sealing surfaces, and cable entries. Aluminum alloy enclosures with stainless steel fasteners simplify these tasks by resisting corrosion and reducing the likelihood of seized bolts or degraded surfaces.

A well-maintained junction box not only ensures safety but also minimizes downtime in critical industrial operations.

Long-Term Value for High-Risk Industries

Investing in a high-quality explosion proof electrical junction box delivers long-term value beyond regulatory compliance. Enhanced safety reduces the risk of catastrophic incidents, while durable materials and flexible design options lower maintenance costs over the equipment lifecycle.

For industries operating in chemical processing, oil refining, offshore oil exploitation, and military hazardous areas, these junction boxes form a reliable foundation for electrical distribution systems. Their suitability for high-power electric heaters and heat tracing systems further expands their role in supporting complex industrial processes.

Conclusion

The explosion proof electrical junction box is far more than a simple enclosure; it is a critical safety device engineered to perform under the most demanding industrial conditions. Through robust aluminum alloy construction, stainless steel fasteners, flexible mounting options, and adaptable cable entry designs, modern solutions meet the evolving needs of hazardous environments.

From chemical plants and oil tankers to offshore platforms and military facilities, these junction boxes enable safe electrical distribution, support high-power applications, and contribute to stable, efficient operations. As industrial safety standards continue to advance, the thoughtful design and application of explosion-proof junction boxes will remain central to protecting people, assets, and processes in high-risk industries.

https://www.minmile.com/

MINMILE